RO pure water system introduce:

(RO water treatment +water tank +edi+water pump )

Reverse osmosis (RO) is a water purification process that uses a semi-permeable membrane to separate water molecules from other substances. Here are some key points about RO pure water systems:

RO systems are used to purify water by removing dissolved solids, contaminants, and other impurities.

The process involves applying pressure to drive water through a semi-permeable membrane, which separates water molecules from other substances.

RO systems typically have multiple stages of filtration, including sediment filters, carbon filters, and the RO membrane itself.

The performance of an RO system can be measured by several parameters, including salt rejection percentage, salt passage percentage, recovery percentage, and concentration factor.

RO systems can be used for a variety of applications, including drinking water systems, high purity water systems, desalination, wastewater treatment, and more.

Commercial RO systems are commonly used in workplaces, schools, hotels, and restaurants to provide high-quality, pure water that is free of sediments, pollutants, and hazardous compounds.

Overall, RO pure water systems are an effective way to purify water for a variety of applications. By removing dissolved solids and other impurities from the water, these systems can provide clean and healthy drinking water or high purity water for industrial processes.

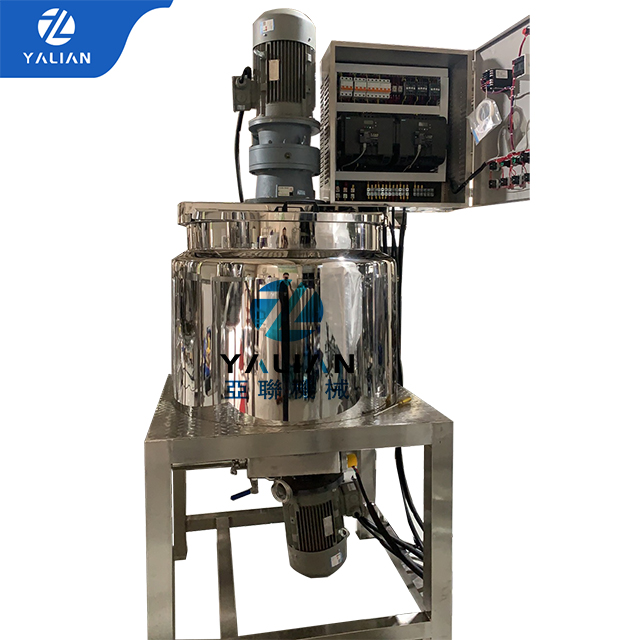

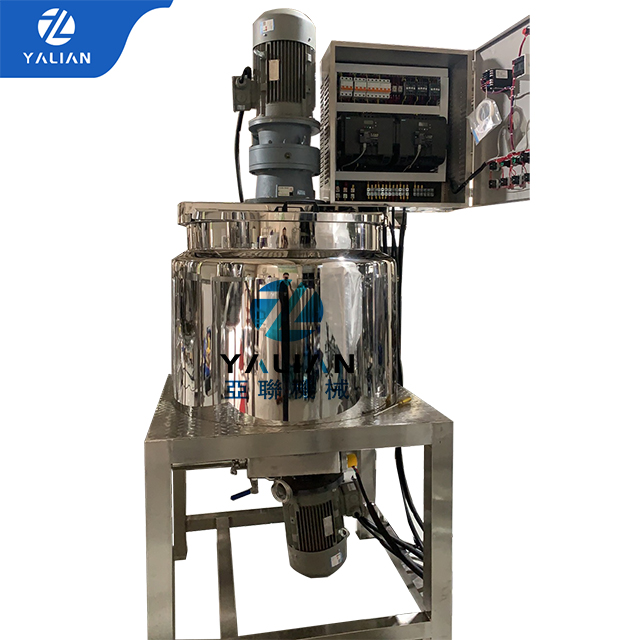

A shampoo mixing tank is a specialized piece of equipment used in the production of liquid detergents such as shampoo, cleanser essence, and shower cream. Here are some features and functions of shampoo mixing tanks:

Stainless steel construction for food-grade applications

Heating, stirring, and vacuuming functions

Material: SS304 and SS316

Power: 0.75kw-75kw

Speed: 0-3000r/min

Assembly equipped with series of paddles types blades, pitched or flat blade of appropriate shape

Vacuum operated models are produced to withstand perfect vacuum during the process for optimum mixing and to eliminate air trap as surfactant has tendency of forming suds

Suitable for 700mm

Capacity: 100L-5000L

Overall, shampoo mixing tanks are designed to mix ingredients thoroughly and efficiently to produce high-quality liquid detergents. They typically have heating, stirring, and vacuuming functions, and are made of stainless steel for food-grade applications. The capacity of these tanks can vary depending on the manufacturer and model.

The mixing tank is an important stage in making shampoo as it is where the ingredients are combined and blended to create the formula.

The key function of it has mixer , homogenizer , heater and cooler system , vacuum system...( However , Different shampoo production processes require different mixing tank with corresponding functions. )

Here are some features of shampoo mixing tanks:

1- 50-100L Movable Shampoo Blender Mixing Vessel Tank (suitable for small business factory )

2- 100-500l shampoo Blender Mixing Vessel Tank with legs or platform and stairs ( according to the factory size to depend on how to design machine )

3- 500l-1000l shampoo Blender Mixing Vessel Tank with platform and stairs (with platform and stairs will easy stand on machine to operation machine )

4- 1000-5000l shampoo Blender Mixing Vessel Tank with platform and stairs ( If u have range more then 3t/day , please choose the size of it )

You can bring your daily capacity to send us inquiry Amanda@yalianmachine.com , we will give to u idea according your capacity .

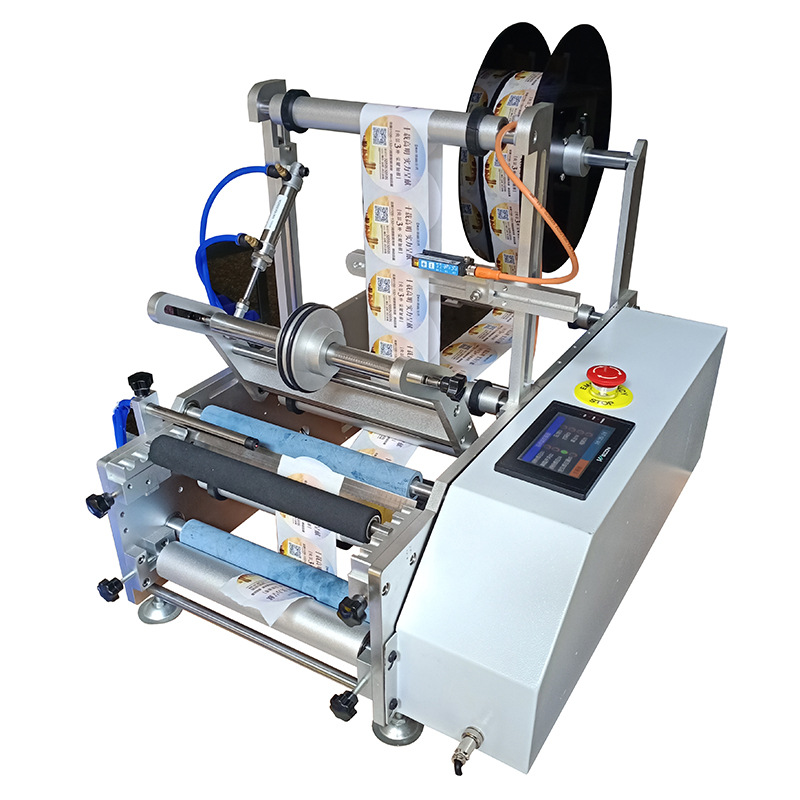

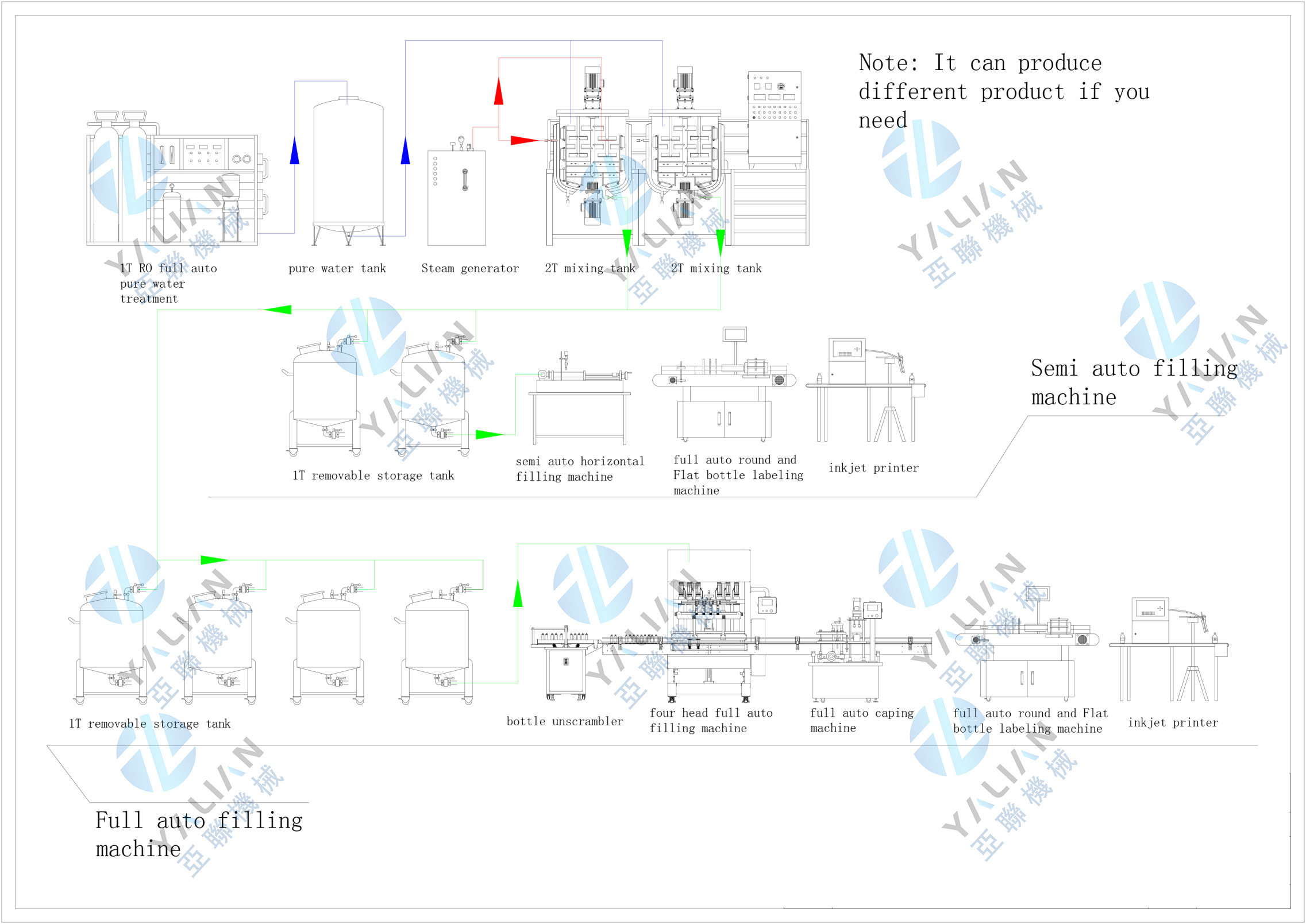

Shampoo filling line machines are used to fill shampoo products into bottles or containers.

Here are some features and functions of shampoo filling line machines:

A: Full-automatic shanpoo filling machine ( check the video )

Fully Automated Filling-Capping-Labeling Production Line:

Filling accuracy is very high with the pneumatic piston booster and volume measurement used in shampoo filing and capping machine.

Filling precision and quantity are adjustable and should be regulated among a big range firstly, then be trimmed.

Can customize the filling machine with specific filling-head number and particular cylinder volume based on the user’s production demand.

Filling range: 50~5000ml

Filling accuracy: ± 0.5%~1%

Tank size: 100~200L

Power supply: single phase, 220VAC, 50/60Hz

Full-automatic Labeling Machine can apply various types of labels on products of different designs, including square, oval, cylindrical, or flat containers.

The best u can bring picture of your bottles inquires with YALIAN MACHINERY , Then has a good advice to u .

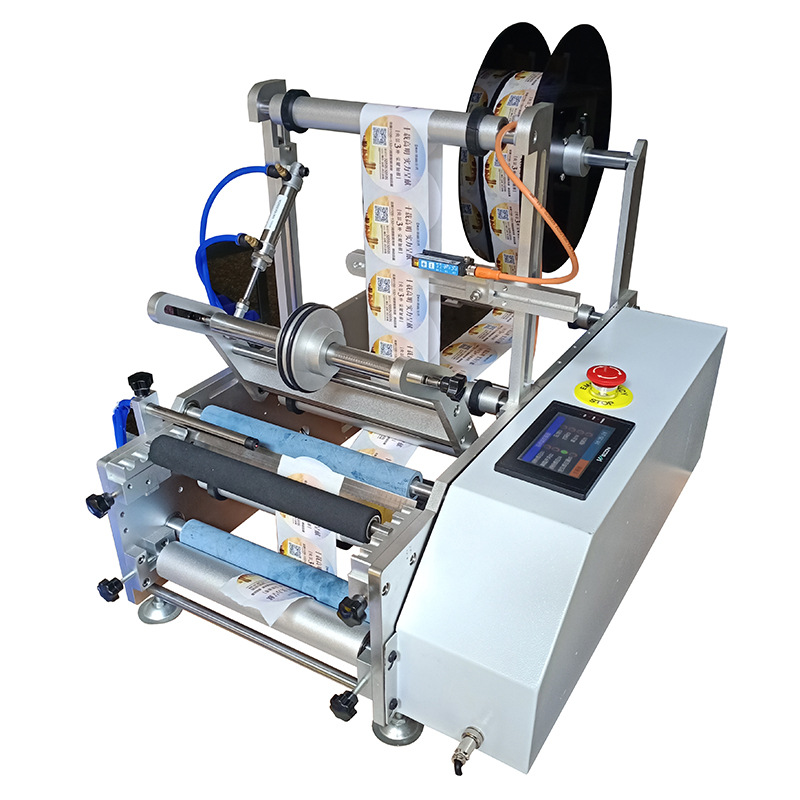

Round bottles labeling machine

Double-side labeling machine

Semi-automatic labeling machine

Capping machine is designed with reference to the advanced international model, with fast capping speed, high pass rate and easy operation. It is suitable for screw caps of different bottle shapes in food, pharmaceutical, daily chemical, pesticide, cosmetics and other industries. Four speed-regulating motors are used for cap feeding, bottle clamping, conveying, and cap screwing respectively. The machine has high degree of automation, good stability, and convenient adjustment. When changing bottle shapes or caps, there is no need for spare parts, and it can be completed only by adjustment (such as matching Capping machine, capable of automatic capping) can be selected according to actual needs.

Principle of automatic capping machine:

Electric control movement, strong stability; equipped with positioning device, cap screwing standard, easy to operate; wide range of locking caps, can lock bottle caps of different shapes and specifications; solve the problem of screw caps for nozzles, pump heads, spray pumps, and hand button nozzles Difficult problem; The rotation speed of the lock cap is adjustable, and the tightness can be adjusted according to different bottle caps.

Features of automatic capping machine:

1. Made of stainless steel material + lightweight aluminum profile

2. The machine has good compatibility and can be applied to various common bottle caps. And it is easy to operate.

3. Excellent flexibility, can be adjusted according to the height of the bottle and the size of the cap, and the tightness can be adjusted according to customer requirements.

4. The rubbing and capping wheel is made of wear-resistant silica gel, which will not damage the bottle cap.

5. It is more advantageous for the duckbill cover (pump head, nozzle, etc.), and the direction of the mouth head is uniform.

6. It can be equipped with a self-pressing capping device.

7. It can be used on the filling production line.

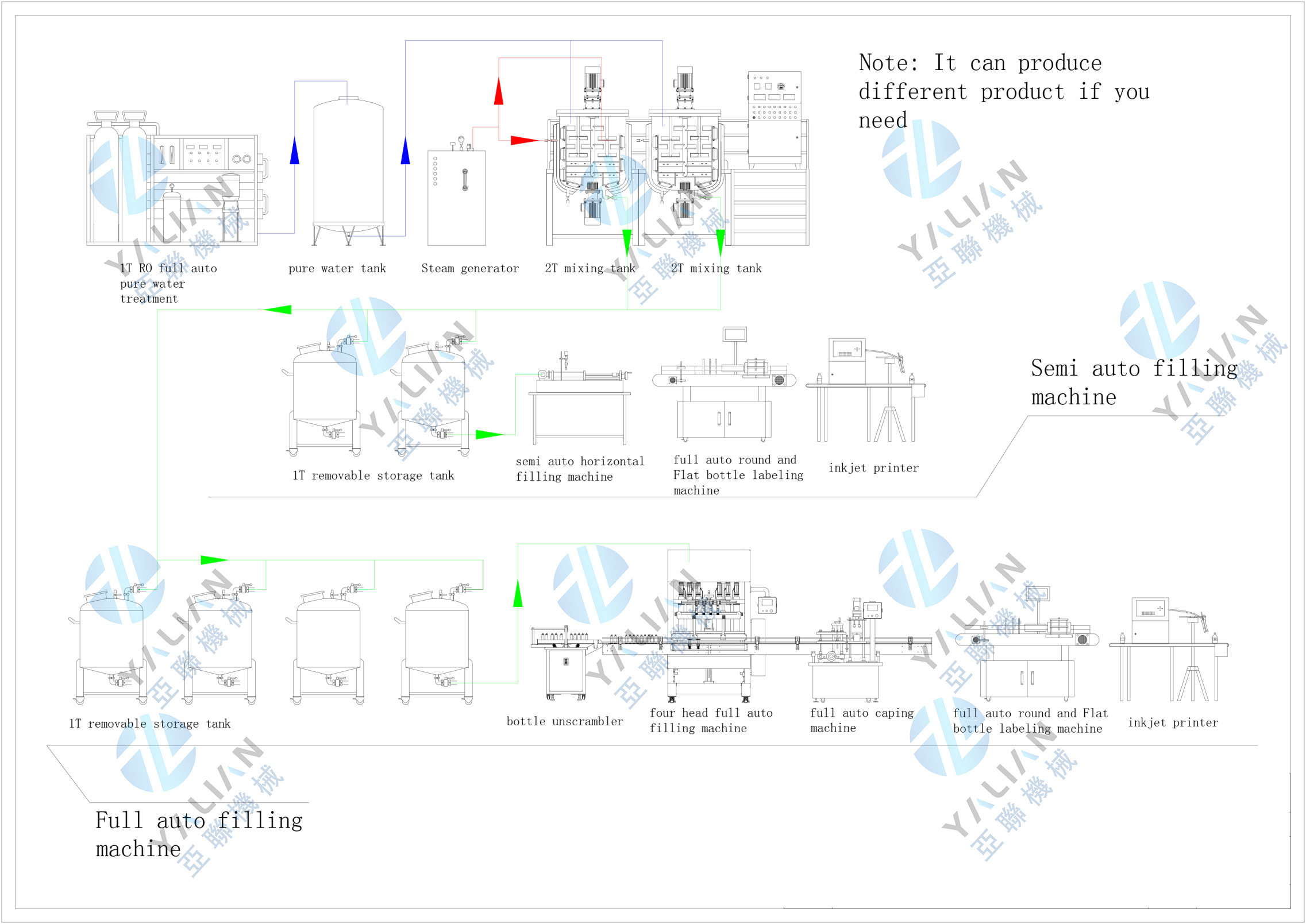

A full shampoo making machine also has others item like Printer , Heat Shrink Film Packaging Machine... A full production line machine in below :

To be knew more techncial about shampoo making machine , please contact YALIAN MACHINERY

Choose YALIAN MACHINERY ,Choose International's Quality !!!