Product Desciption

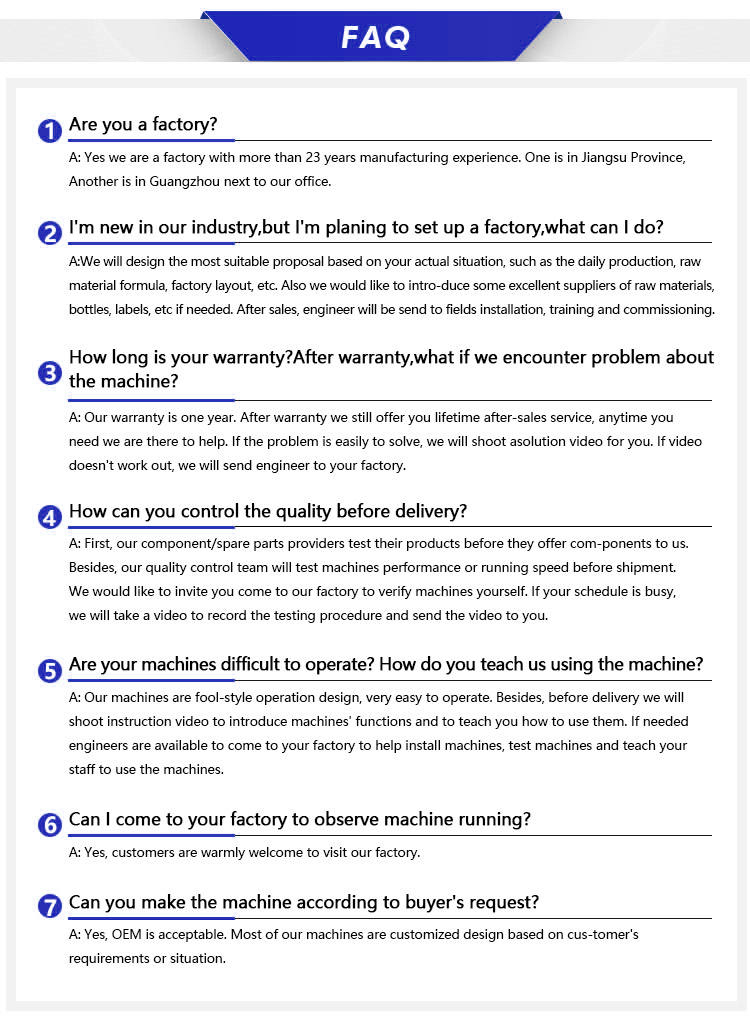

NM Series Vacuum Emulsifying Homogenize Mixer

Working capacity:100L;200L;300L; 500L;1000L

NM Series Vacuum Emulsifying Homogenize Mixer : Mainly Feature

♦ The variety of vacuum emulsification species is diverse, in which the homogeneous system is divided into upper and lower homogeneous, the inner and outer circulation is homogeneous, and the stirring system is divided into one-way stirring and two-way stirring, spiral band stirring; The lifting system is divided into single and two cylinder lifting, and can customize a variety of products that meet the demand and high quality according to customer requirements

♦ Triple stirring is regulated by an imported frequency converter, which can meet the production needs of different processes

♦ The homogeneous structure of the German technology, which uses mechanical sealing of the inlet bilayers with a maximum emulsified rotational speed of 4200 rpm and a maximum shear finesse of 0.2-5um

♦ The vacuum degassing product achieves the aseptic requirements, and uses vacuum suction, especially on the powder material using vacuum suction to avoid flying dust

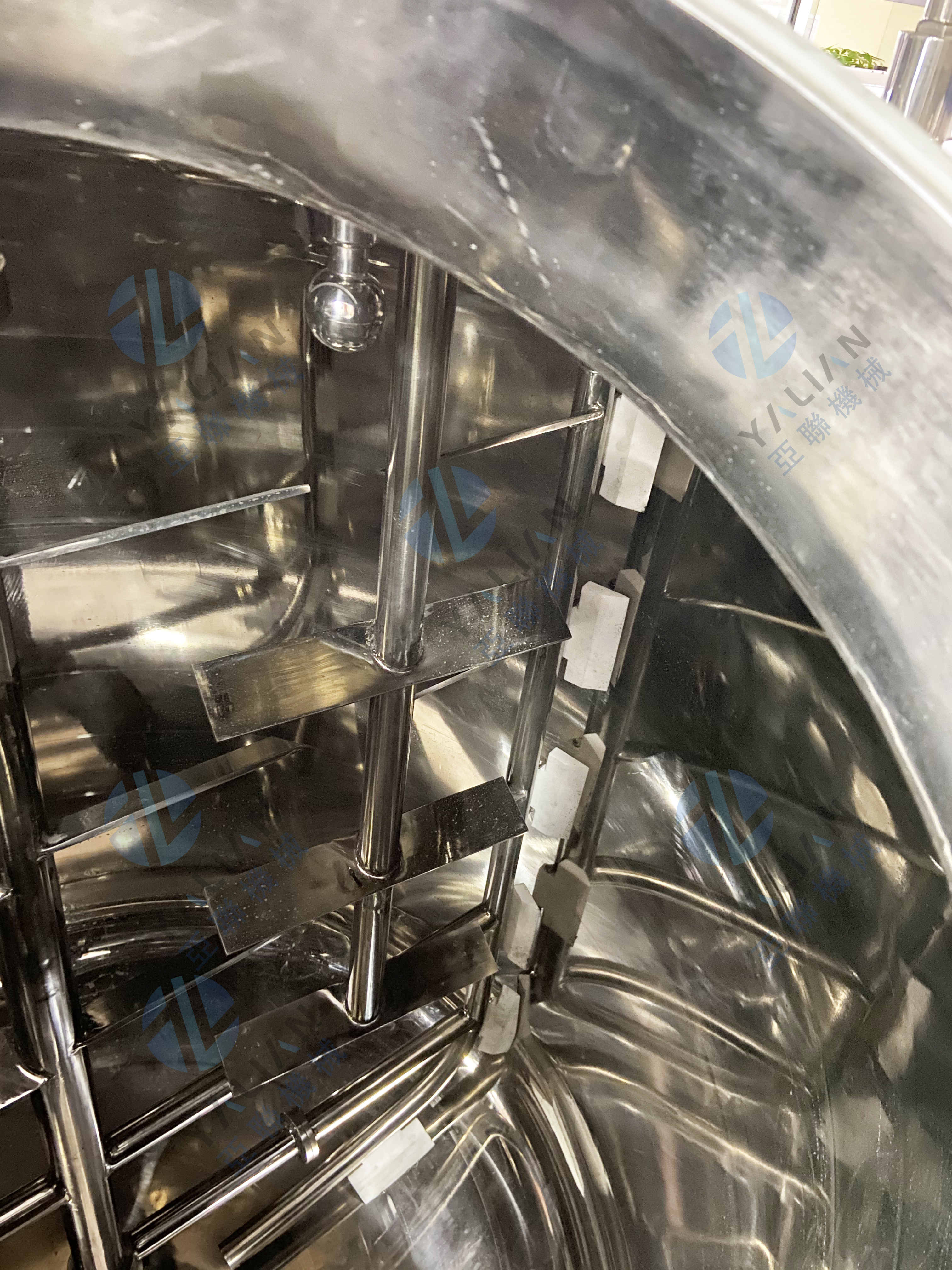

♦ The main pan pan cover can be selected lifting and lifting device, washing is convenient, the cleaning effect is more significant, the pan body can be selected to pour out the material

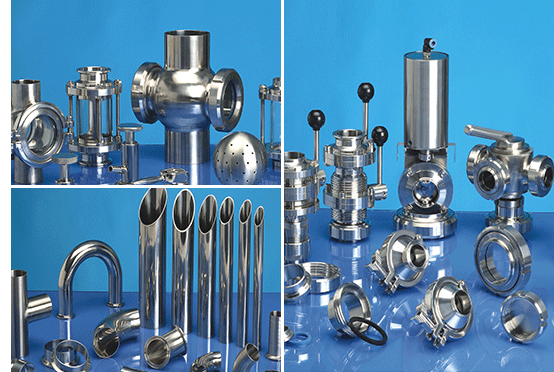

♦ The pan consisted of three layers of stainless steel inlet plates welded, and the cans and tubing were mirror polished in full compliance with GMP requirements

♦ Tank can heat and cool the material according to the process requirements, the heating method mainly has two kinds of steam and electrical heating

♦ In order to ensure more stable control of the whole set of machines, the appliances use import configuration and can fully meet international standards

♦Vacuum homogenizing emulsifier is a complete system with functions of mixing, dispersing, homogenizing, emulsifying and powder absorption. It has electric control system and can also be used with peripheral oil, water phase tank, vacuum, heating/cooling system, etc. It is a special equipment for producing medicinal ointments, high-grade ointments, creams, emulsions, etc.

♦Material is continuously generated with new interface by central stirring in the upper part of the emulsifying pot and PTFE scraper, which always meets the shape of the stirring pot. Through cutting, compression and folding of the scraped material, it is stirred and mixed downward to the homogenizer under the pot body. The material is then cut, shocked and folded by the strong force produced between the cutting wheel and the fixed cutting sleeve which rotates at high speed. During turbulent flow and other processes, the material is cut in the shear joint and quickly crushed into 200 nm-2um particles. Because of the vacuum in the emulsifying tank, the air bubbles generated during the stirring process of the material are timely removed. Vacuum is used to remove air bubbles from the mixing process of the product, which ensures that a glossy, delicate and ductile product can be produced.

♦In the manufacturing process of high viscous emulsifiers, especially cream, ointment and emulsion products, the most common problems are the large particle size of the dispersed phase and the mixing of air into the product during stirring. The large particle size results in the unstable and lack of gloss of the emulsion. Air in the product will make the product bubble, bacterial contamination, easy to oxidize and not smooth in appearance. For two major problems, NM series vacuum homogenizing emulsifier is composed of homogenizing agitator, central blade agitator and scraper agitator with their respective features complementing each other to form the best agitation method to achieve perfect mixtures.

NM Series Vacuum Emulsifying Homogenize Mixer : Mainly Characteristic

Working capacity (L) | Agitator power (kw) | Speed (rpm) | Homogenizer power (kw) | Speed (rpm) | Oil/Water tank (L) | Agitator power (kw) | Speed (rpm) |

100 | 1.5 | 0~65 | 5.5 | 0~3300 | 40/80 | 1.5/1.5 | 0~1400 |

200 | 1.75 | 0~65 | 7.5 | 0~3300 | 80/160 | 1.5/1.5 | 0~1400 |

300 | 1.75 | 0~65 | 7.5 | 0~3300 | 120/240 | 2.2/2.2 | 0~1400 |

500 | 2.2 | 0~65 | 11 | 0~3300 | 200/400 | 2.2/2.2 | 0~1400 |

1000 | 3 | 0~65 | 15 | 0~3300 | 400/800 | 3/3 | 0~1400 |

NM Series Vacuum Emulsifying Homogenize Mixer : Application field

Cream, cosmetics, toothpastes, fruit juices, salt solutions, catalysts, polymeric emulsions, insecticides, herbicides, fungicides, etc.

Grinding equipment, homogenization equipment, shearing equipment, emulsification equipment, dispersing equipment, mixing equipment, stirring equipment, solid-liquid mixing equipment, powder liquid mixing equipment, powder mixing machine, mixed dispersing machine, dispersing emulsifying machine, shear emulsifying machine, emulsifying homogenizer, shear homogenizer, mixed stirring, high shear emulsifying machine, high shear dispersing machine, high shear stirring equipment, high shear emulsifying dispersion equipment, High shear emulsification homogenization equipment equipment series: blender, mixer, dispersant, emulsifier, shearer, homogenizer, grinder, colloidal mill.

Emulsifier have a wide range of applications, such as adhesives, paint coatings, cosmetics, food, pharmaceuticals, plastic resins, printing and dyeing, inks, asphalt and other industries.

Fine chemicals: plastics, fillers, adhesives, resins, silicone oils, sealants, slurries, surfactants, carbon black, defoamers, brighteners, leather auxiliaries, coagulants, etc.

Petrochemical industry: heavy oil emulsification, diesel oil emulsification, lubricating oil, etc.

Daily chemical industry: detergent, concentrated detergent, liquid detergent, various cosmetics, skin care products, etc.

Coating inks: latex paints, interior and exterior wall coatings, water-based oily coatings, nano-coatings, coating aids, printing inks, printing inks, textile dyes, pigments, etc.

Biomedical: sugar coating, injection, antimicrobial, protein dispersant, ointment, health products, etc.

Pesticide and fertilizer: pesticides, herbicides, pharmaceutical emulsions, pesticide auxiliaries, fertilizers, etc.

Food industry: chocolate shell, fruit pulp, mustard, residue cake, salad dressing, soft drinks, mango juice, tomato syrup, sugar solution, edible flavors, additives, etc.

Nanomaterials: nano-calcium carbonate, nano-coatings, various nano-material additives, etc.

Road asphalt: ordinary asphalt, modified asphalt, emulsified asphalt, modified emulsified asphalt, etc.

Cream, cosmetics, toothpaste, fruit juice, salt solutions, catalysts, polymer emulsions, pesticides, herbicides, fungicides, etc.

NM Series Vacuum Emulsifying Homogenize Mixer : Explain in detail

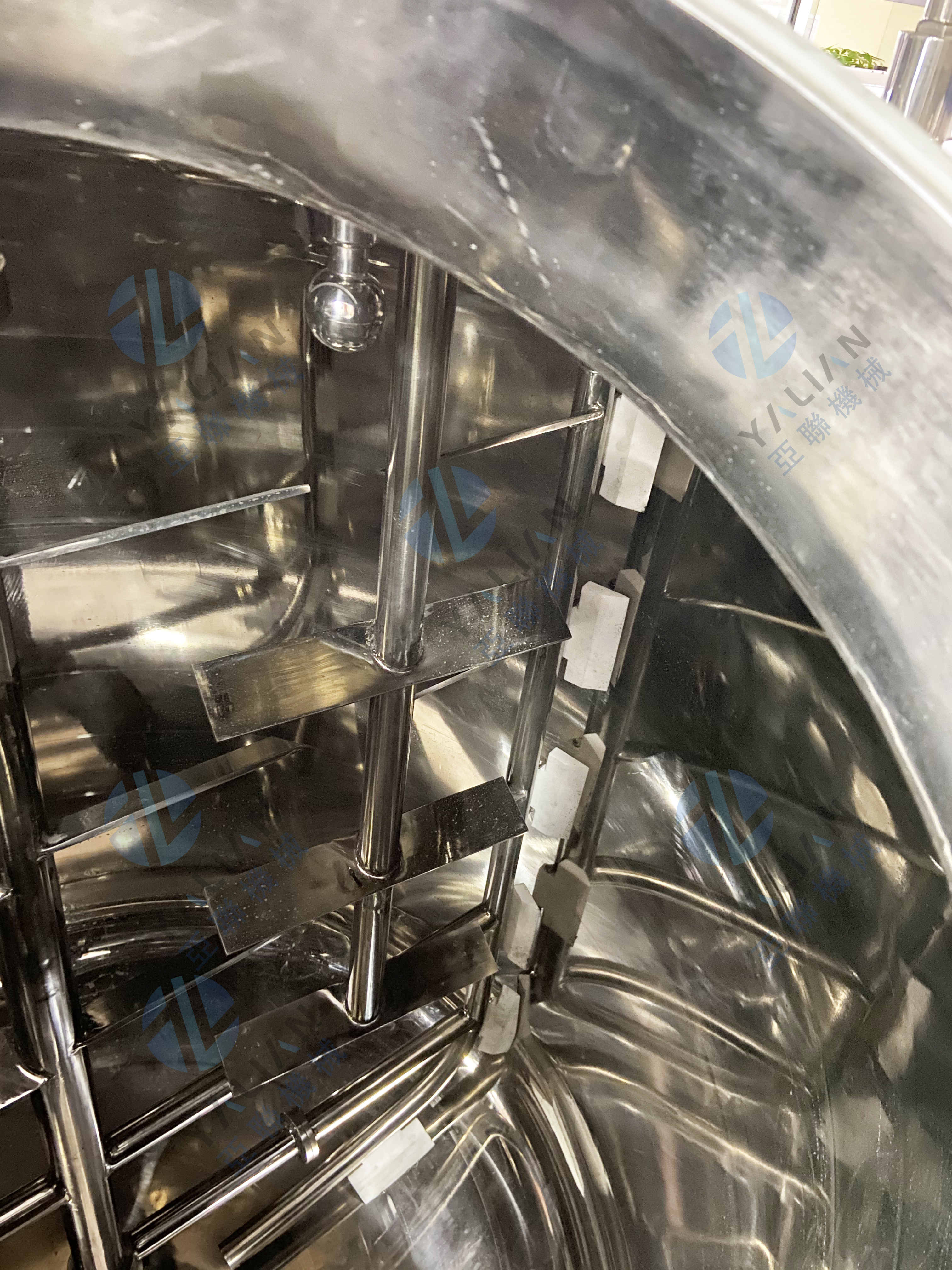

-Mixing system:

1. External mixing form: screw band scraping wall mixing, which increases the efficiency by more than 2/3 compared to ordinary mixing;

2. Internal mixing form: slurry mixing, which makes the flow direction of the liquid more irregular, thereby achieving a good mixing effect;

3. The mixing structure adopts a fully welded method, and the structure of the mixing slurry is arranged at a 45 degree angle. The connection should avoid a 90 degree angle as much as possible to avoid material storage and make cleaning more convenient.

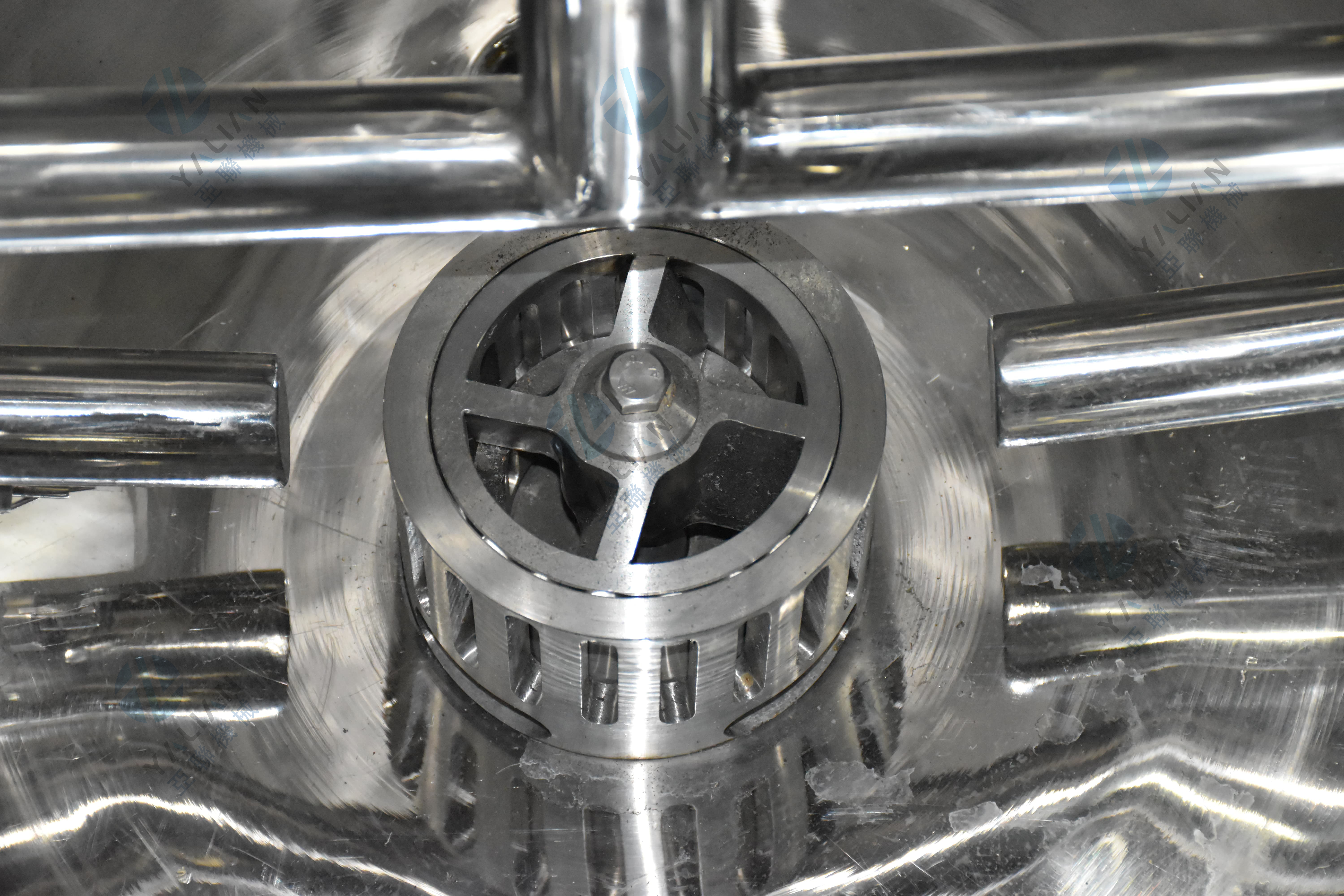

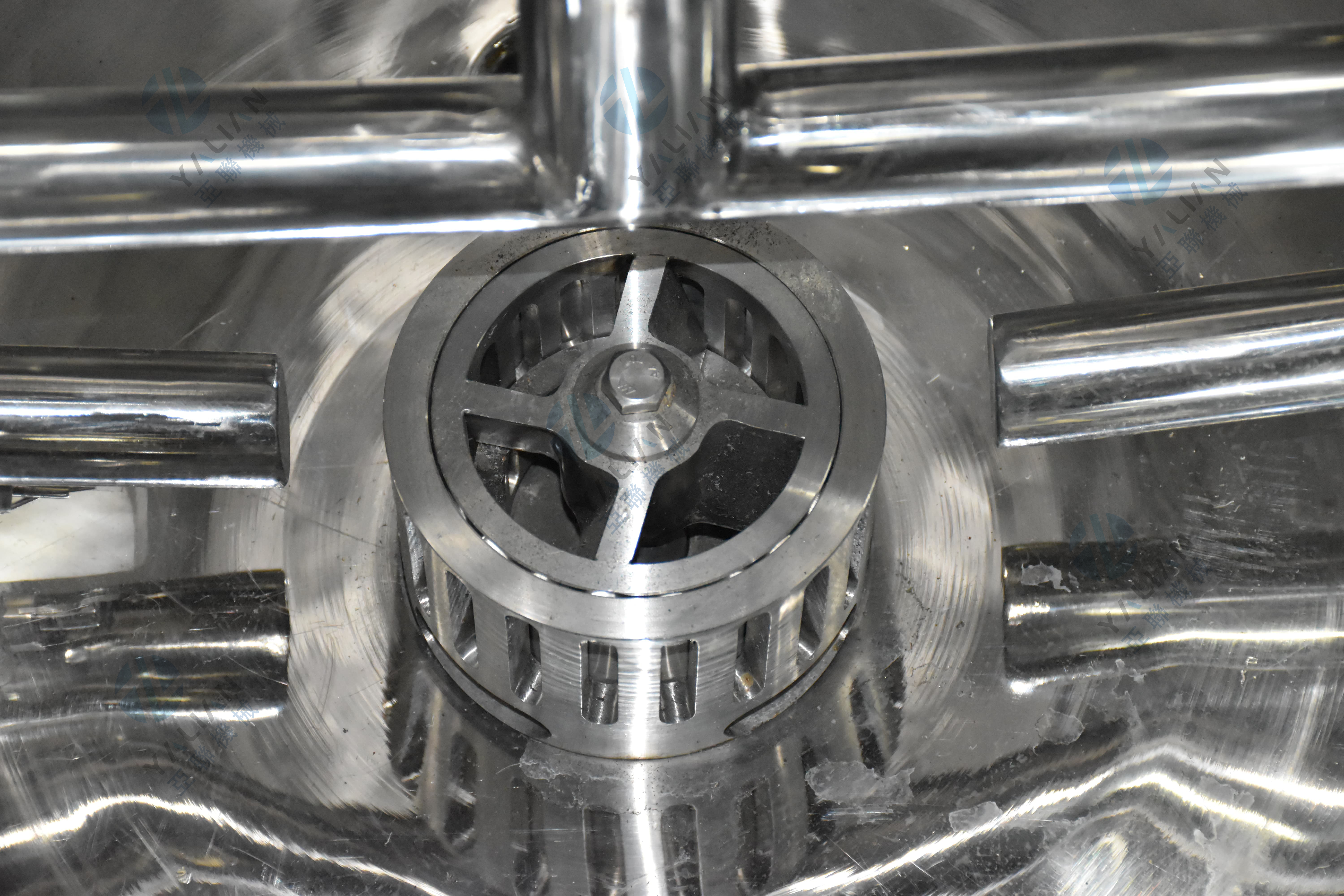

-Homogenizer:

Name: Rotor and stator adopts wire-cutting finish machining high shearing homogenizer

Material: SUS316L

Speed: 0-3300rpm

Bottom & upper homogenizer are optional.

Burgmann mechanical seal, water circulation cooling, cooling and homogenizer synchronization, NSK bearing, Siemens motor, Panasonic frequency inverter

Controller:

Name: Electric control cabinet

Brand: Siemens, Schneider, Omron, Delixi etc

buttons control or PLC touch screen controller design.

Water and oil pot:

-Top eccentric installation.

-The dispersion variable is 1400rpm.

-Inner polishing is above 300MESH level.

-Jacket electric heating Design pressure: 0.3Mpa Working pressure: 0.20Mpa Stirring is high-speed dispersion (or paddle stirring).

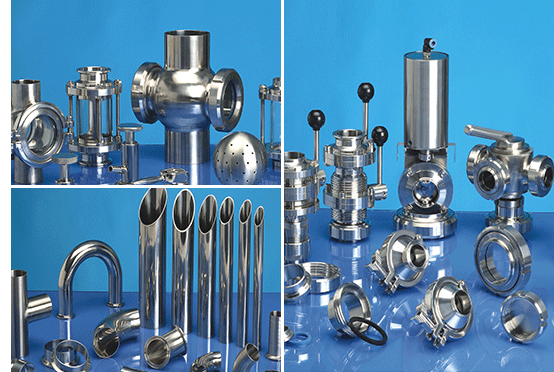

QC of selected raw materials is rigorous:

● Yan keeps raw materials and fittings against acceptance in storage

● has cosmetic equipment manufacturing qualification and the product has passed multiple ISO approvals

● testing equipment is complete, manufacturing process specifications, strict quality tubes throughout the process

NM Series Vacuum Emulsifying Homogenize Mixer : COMPANY EXHIBITION

NM Series Vacuum Emulsifying Homogenize Mixer :ABOUT YALIAN

Guangzhou YALIAN Equipments Co.,Ltd to undertake domestic and international business, technology research and development center to undertake the enterprise's technology research and development work. For more than 80 countries and regions to provide the chemical industry single machine, complete equipment and production line, the whole plant turnkey services. It plays an important role in the construction of domestic and overseas projects and the investment activities of international and domestic partners. Technology research and development center is dedicated to the design and development of dispersing equipment, high shear emulsifying equipment and emulsifying pump, mixing equipment, filling and packaging equipment, powder conveying system, reaction reactor, various pressure vessels and mask machinery. Under the leadership of the company's technology research and development center team, has obtained a number of patents, won a number of awards, and published a number of technical articles in international and domestic industry magazines.

NM Series Vacuum Emulsifying Homogenize Mixer :EMULSIFYING HOMOGENIZER MIXING MACHINE

NM Series Vacuum Emulsifying Homogenize Mixer :CONTACT US