Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine

Capacity :10-3000L

How does the vacuum emulsifier mixer play a role in the toothpaste production process ?

Toothpaste is a daily cleaning product in our life.

We need to use toothpaste to clean our teeth every day, so toothpaste is a daily necessity for us.

The production of toothpaste can use YALIAN Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine to homoegnizer and mix the raw materials.

The YALIAN Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine manufacturer will introduce how the vacuum emulsifying machine plays a role in the toothpaste production process.

Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine refers to shearing, dispersing and impacting materials in a vacuum state. The materials that pass through the operation will become delicate and blend. The vacuum is an especially critical step in the toothpaste-making process. If the vacuum emulsifier mixer fails to meet the vacuum requirements during the production process, the toothpaste produced will contain air bubbles. The vacuum emulsifier mixer allows the material to be evenly dispersed and emulsified instantly in a vacuum state, and no air bubbles are mixed in the production mixing process.

There are two types of toothpaste production processes: two-step paste and one-step paste. The two-step paste method refers to sending the basic materials into the vacuum emulsifier mixer first, then adding the formula materials in turn, and then putting in friction agent, foaming agent and other solid materials for stirring and homogenization. Finally, the essence is put in, and the degassing is completed.

The one-step paste method refers to pre-mixing according to the formula to prepare the oil phase, water phase, and powder phase, and then adding the water phase and oil phase through the pipeline transportation system in turn, stirring and homogenizing, adding powder, stirring again and adding essence, homogeneously Paste making is completed after a few minutes. There is also a one-step paste method called dry one-step paste method, which means that the raw materials are divided into liquid materials, powder materials, and spices. First, the liquid materials are sent to the vacuum emulsifier, and then the powder materials are added. Spices, again for degassing to complete.

Toothpaste is a product that directly enters the human mouth, so there must be no bacterial contamination. Therefore, the toothpaste production equipment must have no dead ends, and the interior should be smooth and stable without residue. The equipment should be kept clean during use, and regularly disinfected and cleaned.

Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine : Main components

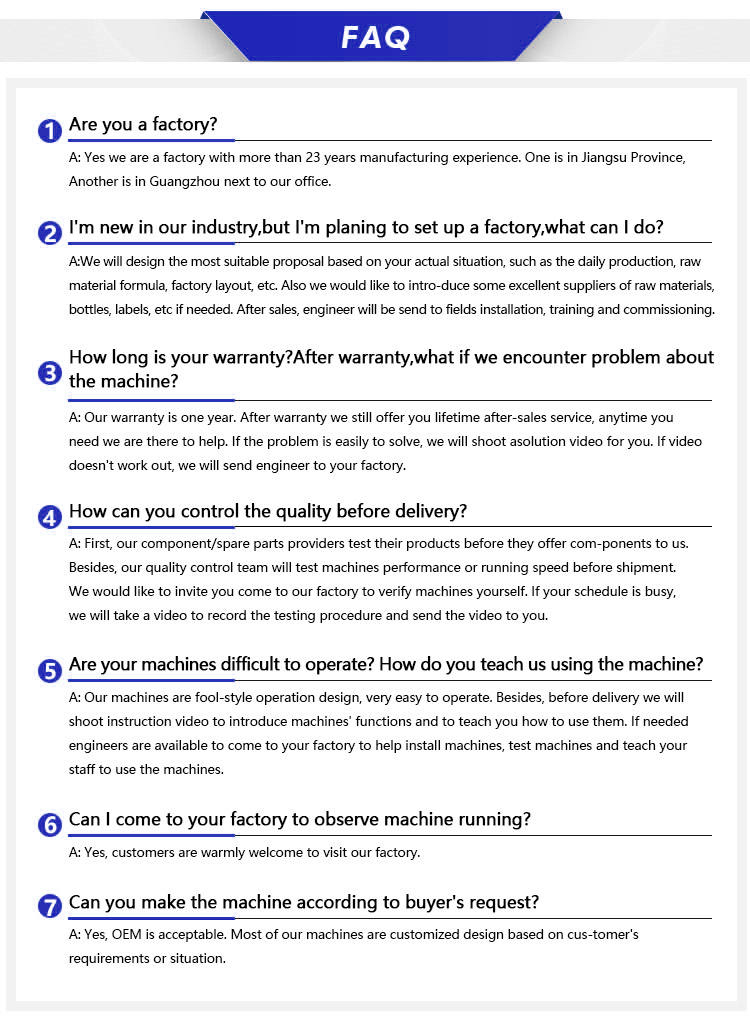

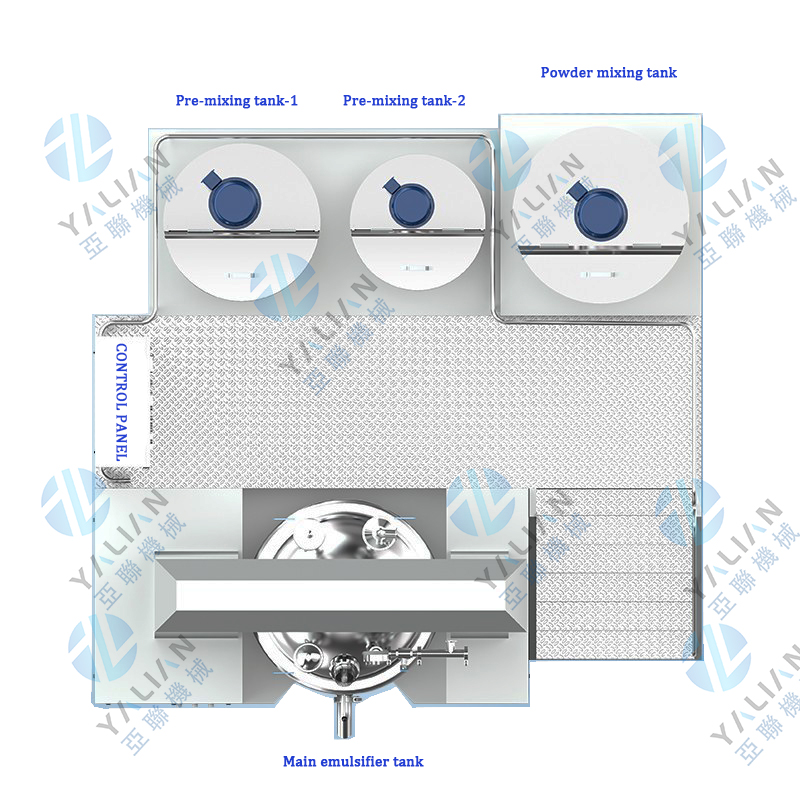

The vacuum emulsification machine is mainly composed of water phase pot, oil phase pot, powder pot and main emulsifying pot, vacuum system, lifting system (optional), electrical control system (PLC is optional), operating platform, etc.

Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine : Performance and Features

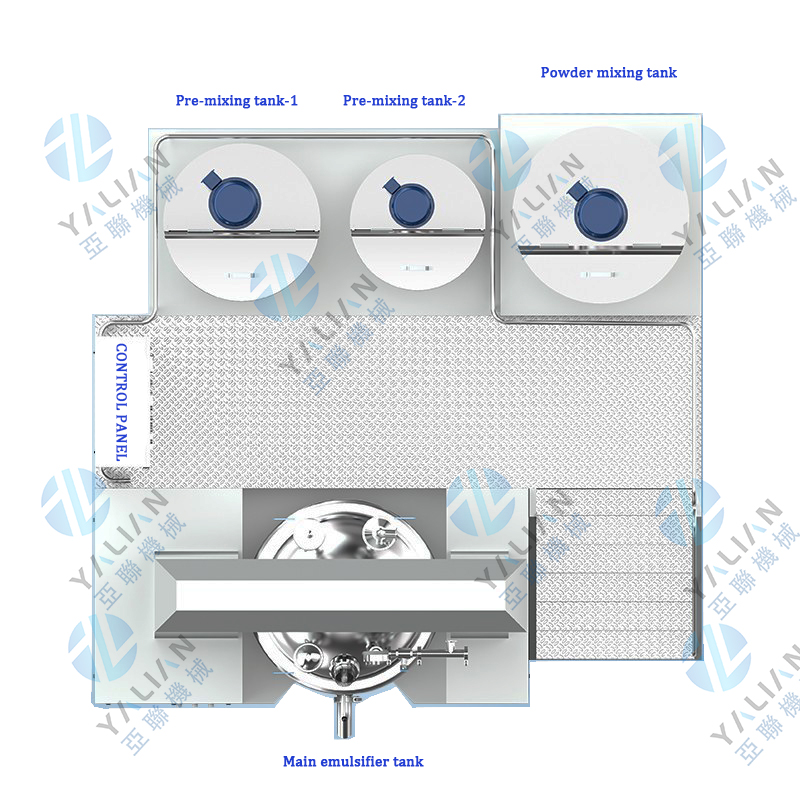

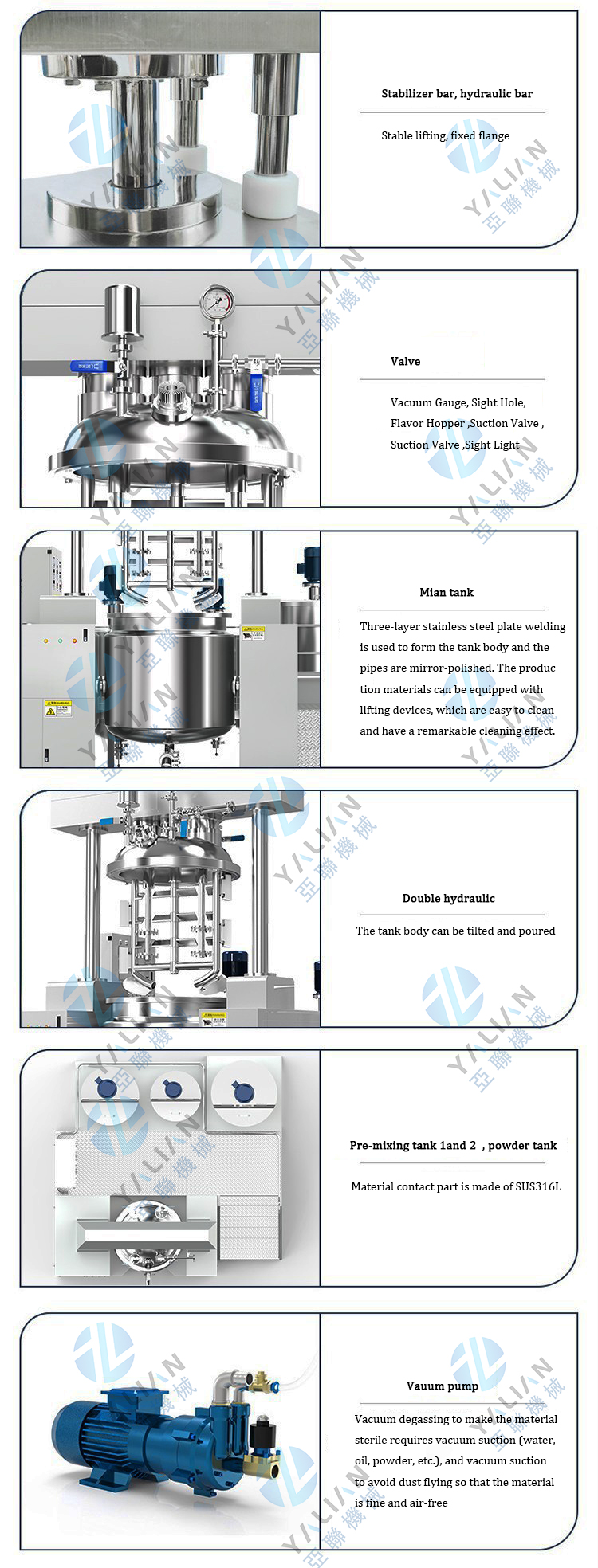

(1) The main tank body has three layers, the inner layer is made of stainless steel 316, the middle interlayer and the outer layer are made of 304, the positive pressure resistance is 0.2MPa, and the negative pressure resistance is -0.1MPa. The jacket is used for heating or cooling, and the positive pressure resistance is 0.3 MPa.

(2) Scraper mixing is a large wall-attached scraper and a central scraper, which rotate in forward and reverse directions, and the speed is 0-65rpm. When stirring, the material can be scraped off the wall of the cylinder, and the temperature transfer is even and full centimeters and turns up and down. Effect.

(3) The high-speed dispenser mixer is placed at the top of the toothpaste making tank , the speed is 0-1500RPM, When the main shaft of the disperser is running at high speed, the upper and lower sides of the dispersing disk are in a rotating state, and at the same time, a turbulent zone will be formed at the edge of 2.5-5mm,T he upper and lower serrations of the dispersing plate perform high-speed shearing, impacting, crushing, and dispersing on materials such as toothpaste raw materials, so as to achieve a state of rapid mixing, dissolution, dispersion, and refinement.

(4) The high-speed homogenizer is placed at the bottom of the paste making pot, the speed is 0-3000RPM, and the gap between the inner and outer rotors is 1- -2mm. After the powder is sucked from the bottom, it is sprayed to the top through the homogenizer, so as to achieve the paste Delicate effect.

(5) The vacuum pump adopts a water-sealed two-stage vacuum pump, and a buffer tank is installed between it and the paste making pot to isolate the materials that are accidentally brought out.

(6) The hydraulic lifting mechanism is a double-cylinder hydraulic differential, which is convenient for overhauling the internal parts of the paste making pot and inspecting the paste in the pot.

(7) Circulating water is used for jacket cooling, the water pressure is controlled below 0.3Mpa, and the temperature is set by the control system.

(8) The outlet is located at the bottom of the toothpaste making tank.

Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine : Product quality comes from advanced manufacturiing equipment

After the materials are mixed and reacted by heating and stirring in the water pot, oil pot, and powder pot, they are sucked into the emulsification pot by the vacuum pump, and stirred by the center of the upper part of the emulsification pot. The wall sticky material makes the scraped material continuously generate a new interface, and then it is cut, compressed and folded by the blade to make it stir and mix and flow down to the homogenizer under the pot.

The material passes through the process of strong shearing, impact, turbulent flow and other processes generated between the high-speed rotating cutting wheel and the fixed cutting sleeve. The material is cut in the shearing seam and quickly broken into 200um-0.2um particles. Due to emulsification The inside of the pot is in a vacuum state, and the air bubbles generated during the stirring process of the material are sucked away in time.

Vacuuming is adopted so that the produced products are no longer mixed with air bubbles during the stirring process, so as to ensure that high-quality products with luster, fineness and good ductility can be produced.

Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine : How to do the toothpaste by toothpaste mixer machine

Check all operating equipment, and start the machine after it is normal.

A. Start the vacuum pump, and start feeding when the vacuum reaches -0.085MP. First suck the oil-water phase liquid material in the saccharin pre-mixing tank into the vacuum reactor, then turn on the frame agitator, and then suck the oil-phase glue in the CMC pre-mixing tank into the vacuum reactor. Note that the feeding speed of the glue should not be too fast to avoid foaming. After the feeding is completed, turn on the high-shear emulsifier and disperser (do not run idle) for several minutes, pay attention to the power meter, then stop it, and then turn it on for a few minutes. After 10 minutes, stop the machine, stop the machine for sampling and test after glue making, and let the glue stand for a while.

B. Before starting the machine for paste mixing, open the frame to stir, and turn on the vacuum pump. When the vacuum reaches -0.085Mpa, suck the powder into the vacuum reactor, and turn on the high-shear emulsifier and disperser at the same time. After adding the powder, turn on the pipeline high-shear emulsifier for secondary grinding and homogenization, and stop it after a few minutes. Add spices and wash the spice liquid bucket with an appropriate amount of edible alcohol. After feeding, turn on the vacuum pump, frame mixer, high-shear emulsifier, disperser, pipeline high-shear emulsifier, and after a few minutes, the special vacuum is in place. After degassing for a few minutes and stopping the machine, the paste making is completed.

C. Use compressed air to press the paste from the kettle to the paste storage tank for later use. At the same time, take samples for testing, make a paste preparation record, and send it to the filling machine through the paste delivery pump.

Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine : Toothpaste production process

1. Prepare oil tank, water tank and powder tank by premixing

Oil tank——according to the dosage of the formula, in the CMC pre-mixing irrigation, the adhesive is pre-mixed in the wetting agent, and after manual feeding, the emulsifying mixer is turned on.

Water tank——According to the dosage of the formula, in the saccharin pre-mixed irrigation, pre-dissolve the water-soluble additives in water, and then put in a certain amount of sorbitol. After adding the ingredients manually, start the emulsifying mixer.

Powder tank—according to the dosage of the formula, measure the friction agent and other powder materials, and pre-mix them in the powder tank for later use.

Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine : Specification and technical

1. Heating and cooling: ≤0.25Mpa water vapor heating or electric heating is passed into the jacket of the pot body; water cooling is passed.

2. Vacuum degree: Negative pressure -0.085Mpa (gauge pressure), the pot should be under negative pressure when stirring.

3. Material: 304/316L stainless steel

| Working capacity (L) | Anchor stirrer power (kw) | Speed (rpm) | homogenizer power (kw) | Speed (rpm) | High speed impeller power (kw) | Speed (rpm) | Vacuum(mpa)

| Lift height (mm) |

5l | 1.5 | 0~65 | 4 | 0~3800 | 2.2 | 0~1500 | -0.085 | 260

|

| ... | ... | 0~65 | ... | 0~3800 | ... | 0~1500

| -0.085 | ...

|

700 | 5.5 | 0~65 | 15 | 0~3800 | 15 | 0~1500 | -0.085 | 1500 |

1300 | 5.5 | 0~65 | 15 | 0~3800 | 22 | 0~1500 | -0.085 | 4500 |

2400 | 5.5 | 0~65 | 30 | 0~3800 | 37 | 0~1500 | -0.085 | 5500 |

| ... | ... | 0~65 | ... | 0~3800 | ... | 0~1500

| -0.085 | ...

|

Please contact to Yalian Machinery

(amanda@yalianmachine.com) if u don't know how to choose which size of toothpaste making machine toothpaste mixer machine to u!!!

Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine : Company

Toothpaste Making Machine Toothpaste Mixer Machine Toothpaste Mixer Machine : EMULSIFYING HOMOGENIZER MIXING MACHINE